In the context of the full implementation of the egg traceability policy, in order to complete the egg identification system, unique code will be necessary to achieve the traceability of eggs. CYCJET 2019 egg inkjet printer is newly launched, and there is not only new identification equipment, but also a complete set of automated egg coding solutions, including independent egg surface coding scheme and boxed egg coding scheme.

The safety and reliability of eggs is the focus of continued attention in all regions of the world. Leading consumers to fully realize that eggs are more than just a commodity, which is the key to improving customer loyalty and improving demand.

By printing brand and egg information directly on the eggs, the manufacturer creates a window that can display the brand and quality, use differentiation to enhance the brand image and influence, increase consumer awareness and viscosity, and thus increase sales.

Eggs need to be traced back to the whole process of production, processing and circulation. This is also an important key point under the national policy and new requirements of laws and regulations to ensure food safety. This is a test for chicken farmers and egg traders. - You will be responsible for every egg you take, otherwise you will not be able to enter the market!

In the face of many problems, which CYCJET gives the overall solution for egg identification?

1. Through the transformation of the conveyor belt, each egg can be placed on the pre-reserved hole position on the conveyor belt. The eggs are manually placed on the assembly line, and the signal is transmitted to the CYCJET inkjet printer for printing through the electric eye. Clear, easy to read and complete logo on the eggs.

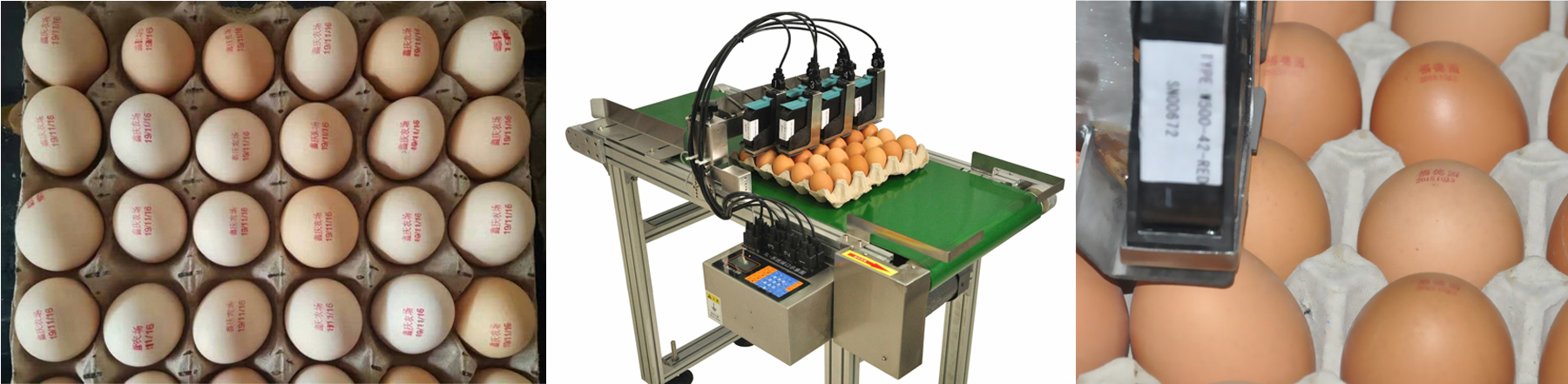

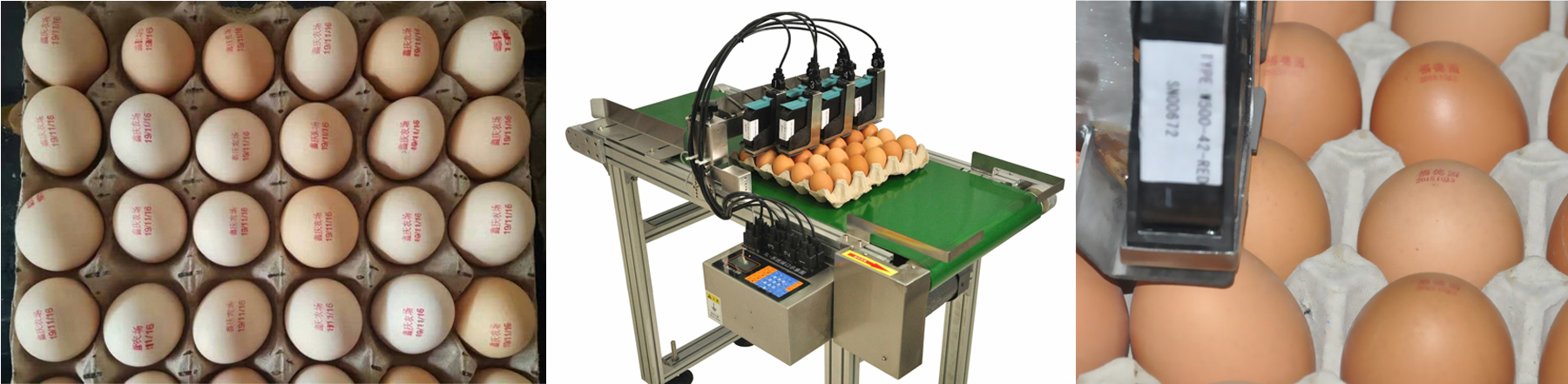

2. Through the servo-controlled stepping motor, the batch printing of the boxed and tray eggs is completed. After the egg tray reaches the predetermined position through the walking mechanism, the nozzle moving mechanism starts to work, and the photoelectric signal is transmitted, and the inkjet printer is sprayed in time. Print the signal to complete the overall assignment of horizontal and vertical eggs.

3, the use of more green laser printer, to avoid the consumption of ink, more safe and healthy, in some of the more automated egg production and processing base, through the non-standard customization of automated equipment (including motion control mechanisms, visual inspection The planning and implementation of details and measures such as the organization and the overall installation structure can quickly realize batch assignment, and the main application is on boxed and pallets.

Through years of technical experience in the marking industry, CYCJET can comprehensively combine products, merchants and consumers to provide a more reasonable, cost-effective and easy to implement integrated solution. We provide comprehensive 365X24 technical support docking.

In the entire process of marking the eggs, what should you pay attention to as a supplier?

The safety and eligibility of consumables. As a food, eggs are essential for every family. In the process of eating, it is necessary to ensure the safety of consumables (inks). It is very important to prevent consumers from ingesting inks and causing some health hazards.

As an egg printer supplier, before each different type of printer is shipped, it will be confirmed with the egg manufacturer and manufacturer. Among them, the model and specifications of the consumables, including color, test report and other information must be The first time is handed over to the company and the supervision and inspection department to ensure ink safety.

Advances in these technologies have improved print quality, better presented important expiration dates and traceability data, and met the changing requirements of government regulations for manufacturers.

CYCJET egg marking machine's overall marking solution can meet the coding requirements of different types of eggs, and provide high-quality coding for manufacturers and processing plants to enhance the brand image and enhance the comprehensive competitiveness in the product market.

From the user's point of view, how to choose the egg printer

There are two common choices, one is a small character printer and the other is a high- resolution printer. We must not only look at the printing effect and quality, but also the price, which sometimes becomes a very important decision factor when purchasing users.

High-resolution inkjet printer, also known as the Piezo inkjet printer, has a dot-shaped font, a variety of colors, and a variety of inks, such as red, blue, purple, and black. Select, print fast, can achieve high-speed non-contact code on the egg, can print graphics, text, numbers, LOGO and other information.

In addition, the problem we should pay attention to is to check the supplier's qualifications, as well as the ink test report, to ensure that the ink is owned and meet the ROSH test, MSDS and other reports, because eggs as food, the general requirement is that the printer must support the "edible type". "Ink", to ensure that foods meet safety standards to the greatest extent, will not have a negative impact on consumers.

With the development of industrial intelligence, the market price of egg inkjet printers has also changed.

With the rapid development of automation equipment, from chicken farms to egg production and processing manufacturers, a large number of equipment has been updated, becoming a more intelligent, efficient and labor-saving solution, how to combine existing resources, through communication, online It is also important to change the code to achieve deeper identification and anti-counterfeiting, anti-mite and marketing functions.

Different choices, different costs, small-capacity inkjet printer supporting nozzle moving mechanism, the whole set price is about 50,000 yuan, can realize batch automatic egg assignment, according to the type of equipment type difference, there will be a certain price space, belonging to A more cost-effective option.

Or you can let the supplier, or the egg printer manufacturer come to the site to give demonstrations and tests to the customer. At this time, you can see the effect and the actual coding speed, as well as the operating status of the whole machine, so that you can understand the whole set of eggs more intuitively. Coding system.

The multi-nozzle high-resolution jetting machine is equipped with a conveying device, and the whole pallet and the whole pallet are sprayed with high efficiency, but the overall price is also expensive. According to the functional configuration, the price range is about 100,000 yuan.

The choice of high-resolution inkjet printers is more in consideration of the overall working efficiency. The multi-nozzle high-resolution inkjet printer can be fixed on the conveyor belt through the gantry bracket, and the whole inkjet code can be realized at one time when the whole tray of eggs passes. Efficiency is much higher than small characters.

Today, as the identification equipment gradually matures and the overall market transparency gradually increases, it becomes more important to purchase egg coding equipment and selection. Everyone must have some in-depth understanding of the equipment requirements before purchasing, in order to be fast and accurate. Purchase a suitable, reliable, durable, and high-quality overall identification device.