Laser marking machines: Ending the problem of code detachment and providing a crucial line of defense for product security!

2025-12-26source:access:245

Batch Code Detachment: A Small Label, a Big Problem!

Imagine this: Your product goes through production, warehousing, and transportation, finally reaching the consumer. However, the crucial batch code (lot number, production date, and expiration date) becomes blurred or even completely detached during transit.

What are the consequences?

Consumer confusion and complaints: Inability to identify product information leads to a sharp decline in trust.

Companies face recall crises: Inability to trace batches forces the recall of entire product batches, resulting in high costs.

Brand reputation suffers: Safety and quality control are called into question.

This is not a hypothetical situation. Industry data shows that over 67% of product recalls are directly caused by unclear or detached labels! A small batch code can trigger enormous risks.

Why are traditional marking methods inadequate?

Traditional marking methods are highly susceptible to failure when faced with the following challenges:

Environmental humidity erosion: High humidity significantly reduces ink adhesion.

Ink quality defects: Low-quality ink has poor resistance to physical and chemical stresses, making it prone to peeling and dissolving.

Solvent contact: Contact with solvents such as alcohol and cleaning agents can cause the ink to dissolve and disappear.

Transportation wear and tear: Friction between packaging can gradually wear away the ink markings. Especially under harsh conditions such as freezing and high humidity, the detachment rate can reach as high as 15%, becoming a "ticking time bomb" in the product distribution process.

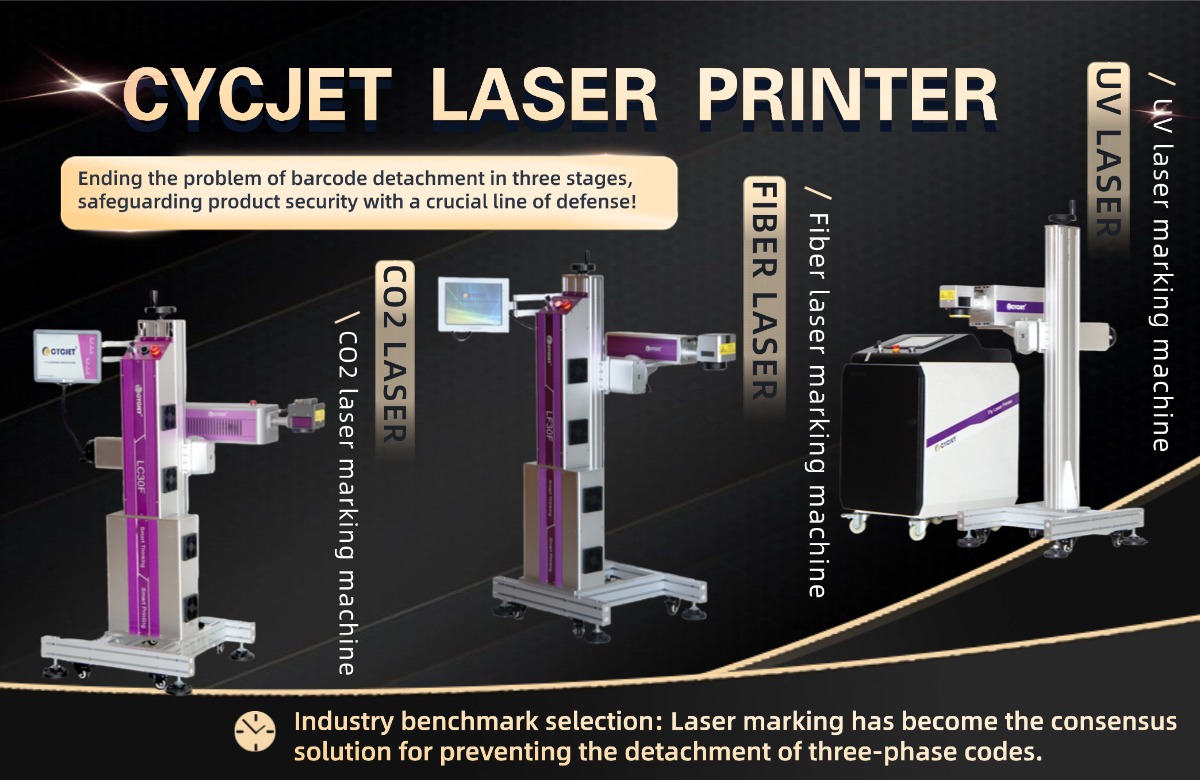

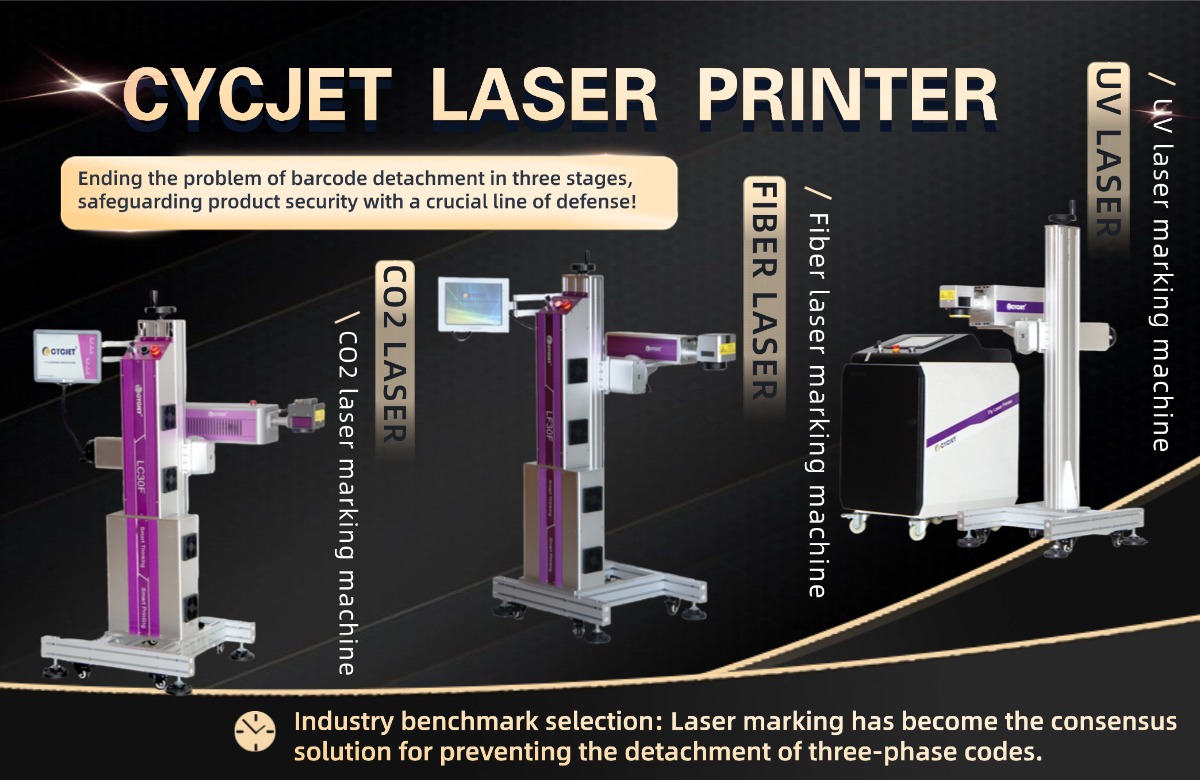

Laser Marking Machine: A Reliable Solution for Imprinting "Permanent Genes" onto Three-Phase Codes

To completely eliminate the problem of three-phase codes peeling off, a fundamental change in the marking method is necessary.

UV laser marking machine is the fundamental solution to this pain point:

Permanent, non-removable markings: Lasers use high-energy beams to physically mark the surface of packaging materials (by altering the molecular structure or removing the surface layer), creating permanent information that cannot be erased or peeled off.

Wide range of material compatibility:

UV laser coding machine: excels at processing glass, plastics (cosmetic bottles, pharmaceutical bottles), pharmaceutical aluminum foil, etc.;

Fiber laser marking machine: specializes in metal instruments, tool materials, etc.;

CO2 laser marking machine: suitable for non-metallic materials such as pharmaceutical cardboard packaging.

Real-world case study:

A well-known food company successfully solved the persistent problem of date labels falling off frozen products during transportation by adopting laser marking technology, avoiding over 3 million yuan in return losses annually.

Dual protection system: Ensuring every code is perfect and reliable; achieving zero label detachment requires a more comprehensive guarantee.

Intelligent Vision Inspection System: Visual inspection performed immediately after laser marking.

• Real-time identification: Detects defects such as misprints/missing prints, incomplete/deformed characters, positional deviations, and insufficient clarity.

• High-speed and precise: Detection speed up to 20 items/second, accuracy >99.999%.

• Automatically rejects defective products, adding a second layer of security to product quality.

Industry Benchmark Selection: Laser Marking Machine Becomes the Consensus for Solving the Problem of Three-Stage Code Detachment

Leading domestic pharmaceutical companies, in their recent tenders for laser marking systems, have put forward clear and stringent technical requirements:

• Two lines of three-stage codes (batch number + date + expiration date) must be clearly printed in three locations.

• The marking pass rate must be >99.5%.

These requirements clearly point to a zero-detachment, highly reliable, and easily traceable laser marking solution, representing the latest industry standard.

Choosing a laser marking machine means choosing ultimate protection for your product's traceability codes.

For industries such as pharmaceuticals and food, where safety and compliance are paramount, clear, permanent, and indelible traceability codes are the lifeline of product distribution and the cornerstone for companies to avoid recall risks and maintain brand reputation.

Laser marking technology, through its inherent permanent marking capabilities and continuously improving reliability design, fundamentally solves the problem of traceability codes becoming illegible or detached. It's no longer just a piece of equipment; it's a crucial link in your product safety system.

Let every line of your traceability code be proof of your product's reliability. Choose a laser marking equipment to build a solid defense for your product safety and brand reputation.

About CYCJET:

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Keywords :

UV laser marking machine

UV laser printer

Laser marking equipment

Laser coding machine

High-speed laser marking machine

Flying laser marking machine

CO2 laser marking machine

Fiber laser marking machine